A memorable sight years and years ago was a field of flax in bloom across a plantation-style farm on the outskirts of a city in Virginia. The fields were full of bright blue flowers, historically grown to then create linen. The farm has since gone under a sprawling mall and commercial development. The memory remains.

A memorable sight years and years ago was a field of flax in bloom across a plantation-style farm on the outskirts of a city in Virginia. The fields were full of bright blue flowers, historically grown to then create linen. The farm has since gone under a sprawling mall and commercial development. The memory remains.

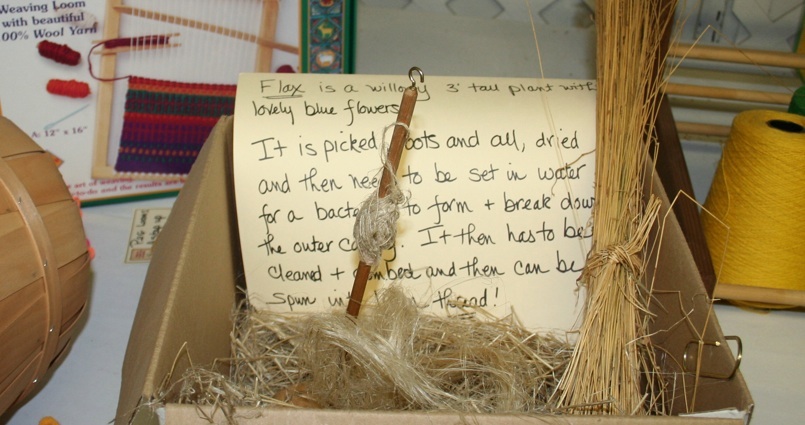

Someday I hope to see acres of flax in flower again. Wondering about the process to create linen from these plants sparked a lively conversation with the folks gathered at the Storrowton Village booth during the 2011 Fiber Festival of New England.

It’s work to transform plant material into filaments.

The process – which is on tap for a future report – calls for “retting” – loosening the fiber from a plant stalk with water, time and bacteria – basically, a controlled rotting process. “Scutching” involves crushing woody parts. Heckling combs (or hackles) weed out unwanted bits to achieve the end result – long, soft flax fiber to spin, ply, weave or knit. Linen as fabric has a soft sheen and is cool and soft to touch.

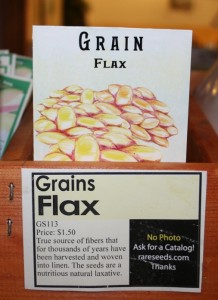

On a recent field trip to Comstock, Ferre & Co. in Connecticut, now part of Baker Creek Heirloom Seeds of Missouri, happening on a packet of flax seed seemed pure magic. The small envelope contained enormous potential for a growing a field of flowers and fiber.

On a recent field trip to Comstock, Ferre & Co. in Connecticut, now part of Baker Creek Heirloom Seeds of Missouri, happening on a packet of flax seed seemed pure magic. The small envelope contained enormous potential for a growing a field of flowers and fiber.

A footnote: The fibers when newly processed look “blonde” – the origin of the word “flaxen.”